Water Jet Cutting Technology

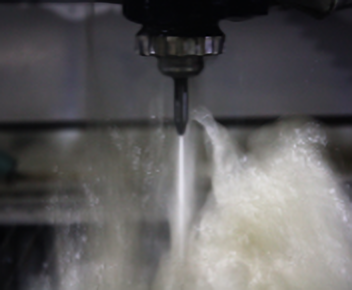

Our state-of-the-art water jet cutting machines can cut a wide variety of materials.

Processing of Various Materials & High Yield

Because waterjet cutting uses the water containing powdered abrasive to cut, it can cut metals such as stainless steel (SUS) and aluminum and glass, rubber, plastic, and other materials.

Since heat is not affected by heat, materials are not easily distorted, and there is no risk of melting, burning, discoloration, or generating toxic gases. Its ability to freely design the shape of the material to be cut and its placement on the material allows for increased yield of the material.

Respond to Mass Production to Small-lot & Express Orders

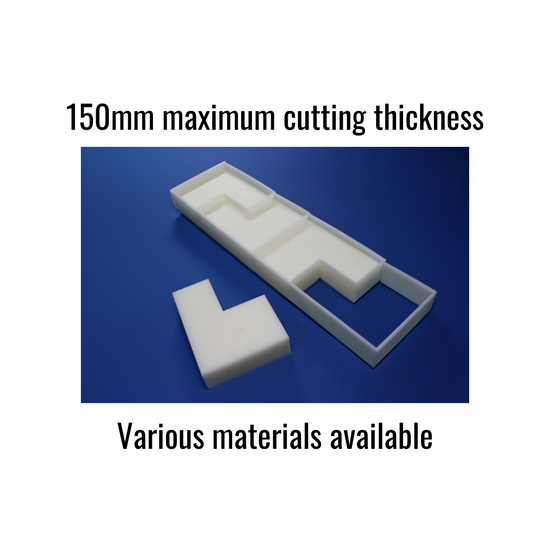

Our waterjet cutting machines can cut materials up to 150 mm thick. We can quickly respond to various needs, from mass production to small-lot and express orders.

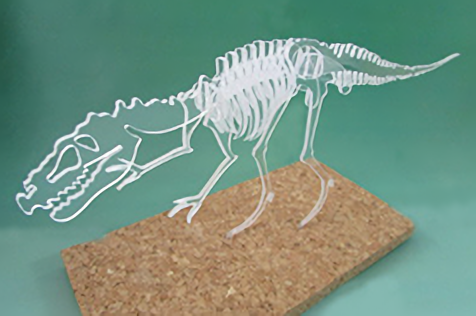

Water Jet Cutting Examples

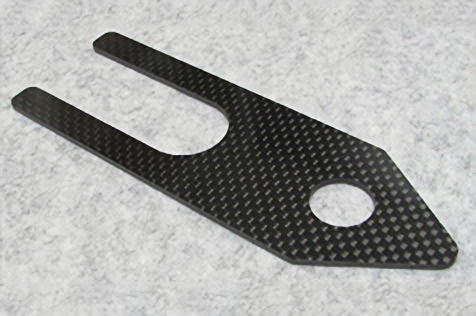

CFRP and GFRP can be cut without fluffing and delamination.

Titanium alloys can also be cut without thermal effects.

Refractory bricks are cut into a circular shape.

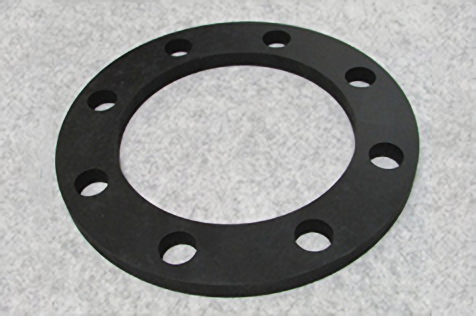

Nitrile rubber (in sheet form) was cut into circular gaskets.

PET was cut into a dinosaur skeleton.

MC nylon (blue) was cut in the shape of Ohkita Technologies.

Case Study

Succeeded in processing glass cutting, which was impossible for other companies

A customer asked another company to cut glass. However, no matter the cutting method, the glass broke and shattered during processing. Therefore, the customer came to our company for help.

At first, the glass cracked and broke into pieces during water-jet processing, However, we finally found an acceptable solution after repeated trial and error under various processing conditions.

We will help you choose the best manufacturing process for your needs.

Available in both English and Japanese.

Our professional staff will provide you with detailed customer service.