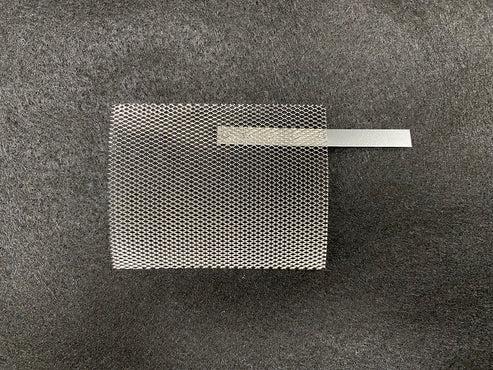

Current Collector Assemblies

Industry's Highest Quality Current Collector Assemblies

Welding is essential to producing current collector assemblies, but quality control requires expertise and time. We purchase materials for expanded nets and perforated metals, order them from manufacturers, and then cut, clean, and weld them in-house. Our extensive experience and expertise in each process ensure our customers receive top-quality current collector assemblies.

Case Study

Transfer welding and assembly work to us

Some current collectors and lead wires can be difficult to weld together, depending on the combination of materials. Customers often request us to take over assembly that other companies were unable to handle.

Quality Assurance

JIS Q 9100 Certified

Our Shimamoto Factory was certified in September 2015 for JIS Q 9100. This means it meets the requirements for quality management systems in manufacturing specialized battery parts for civil aircraft and space applications.

Production & Quality Control Systems

We take a centralized approach to production and quality control. From receiving an order to delivering the product, every stage is managed through an integrated database. Our manufacturing records ensure that our products are all traceable.

We will help you choose the best product for your needs.

Available in both English and Japanese.

Our professional staff will provide you with detailed customer service.