Welding Technology

We manufacture stainless steel and aluminum cases by combining welding technologies such as laser, GTA, and spot welding with precision pressing. The result is overall superior quality, better mating, and joints.

High-mix, Low-volume Production &Lower Cost, Shortest Delivery Times.

We manufacture cases by welding and bending instead of drawing, eliminating the process of metal mold designing and manufacturing.*

Therefore we can manufacture cases at the industry’s lowest total cost and shortest delivery times.

We can flexibly respond to unique situations such as deep cases, large aperture length-to-length ratios, dimension changes frequently, high-mix, low-volume production, etc.

*jigs are required

The Best Quality Control System in The Industry

We perform helium leak tests for all products to ensure airtightness is perfect. We can also handle unique processes and have more than twenty years of experience in fine welding (0.1 mm or less) for applications such as safety valves.

Penetrant inspection can be performed as another type of airtightness test.

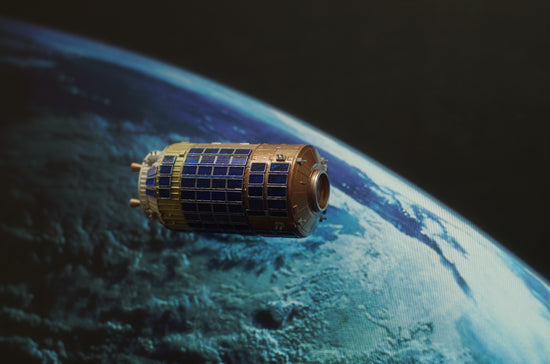

Proven High Reliability

They are mainly used as battery cases for lithium-ion batteries and in various fields, from general to aerospace applications where high reliability is required.

We offer small lots production of a few pieces for prototypes to mass production of several thousand pieces with low metal mold costs and short delivery times.

Insulation coating is also available upon request.

Case Study

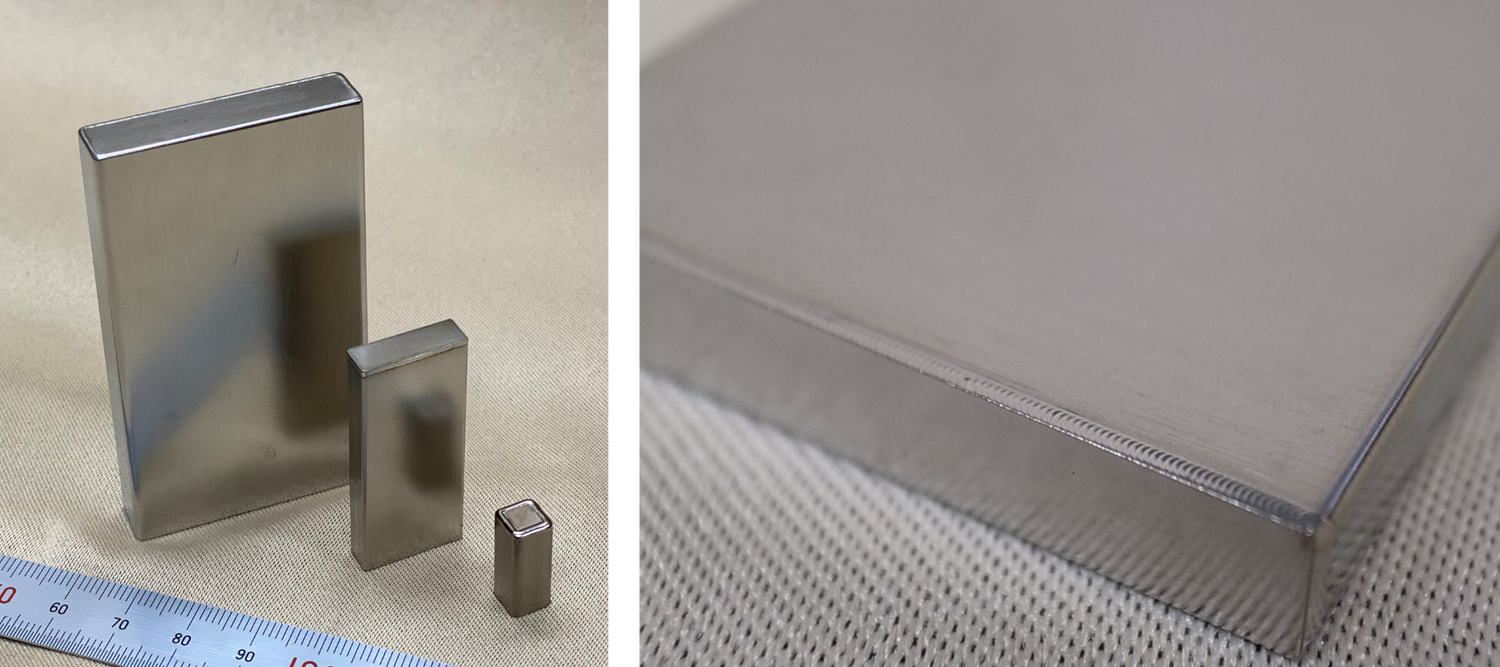

Titanium Alloy (Ti-6AL-4V) Battery Case

While Ti-6Al-4V alloy has excellent mechanical strength, it is challenging to draw deep and extremely difficult to weld. Our technology enables sound welding, making it possible to produce the battery case shown in the following photos.

We will help you choose the best manufacturing process for your needs.

Available in both English and Japanese.

Our professional staff will provide you with detailed customer service.